Mining Tools — A Guide to Mining Equipment and Mining Machines

"Mining tools" is a general term that refers to all the equipment and machines used to extract minerals from the earth. These tools are essential for accessing and processing various natural resources that support modern life.

From everyday items like smartphones and cars to critical energy sources like coal and uranium, mined minerals are integral to our daily lives. In fact, about half of the United States’ energy supply comes from these resources, highlighting their importance in our energy infrastructure.Whether it's for extracting precious metals or fossil fuels, mining tools and equipment play a crucial role in every step of the process.

To better understand how these tools are used, it's important to first explore the different types of mining methods. Each technique requires specific tools tailored to its unique challenges and objectives.

This guide will walk you through the main mining techniques, followed by an in-depth look at the tools and machines used in each type of operation.

Types of Mining Methods

Mining can be broadly categorized into four types: underground, open-pit (surface), placer, and in-situ mining. The choice of method depends on the type of mineral being extracted and its depth beneath the surface.

While each method has its own set of tools, they all follow a basic sequence of steps:

- Extraction. This involves digging, drilling, or blasting to access the minerals.

- Material Handling. After extraction, materials are sorted, with target minerals sent to processing areas and waste materials discarded.

- Material Processing. Minerals are then refined, crushed, or smelted to prepare them for use in products.

Surface Mining Methods

Surface mining is used when minerals are close to the earth’s surface. Common techniques include:

-

Strip Mining. This method removes layers of overburden to reach minerals like coal. It's often a precursor to open-pit mining.

-

Open-Pit Mining. Large pits are created using explosives to access deeper deposits, such as silver or copper.

-

Quarrying. Used for extracting hard rocks like granite or marble, quarrying typically follows open-pit methods.

-

In-Situ Leaching (ISL). This technique dissolves minerals in place, commonly used for uranium extraction without removing large amounts of rock.

-

Placer Mining. This method uses water and pans to separate gold from sand or gravel, taking advantage of gold's higher density.

Open-pit mine | Source: Adam Rhodes on Unsplash

Open-pit mine | Source: Adam Rhodes on Unsplash

Underground Mining Methods

Some minerals cannot be reached through surface methods, so underground mining is used instead. This method involves working in confined spaces and requires specialized techniques:

-

Blast Mining. Explosives are used to break up rock and create access points.

-

Room and Pillar Mining. Miners create pillars to support the ceiling while extracting minerals around them.

-

Retreat Mining. This involves removing pillars to extract more minerals, but it can be dangerous due to potential cave-ins.

-

Block Caving. A large-scale method where rock collapses into a void, making it easier to extract minerals.

-

Cut and Fill Mining. Miners excavate horizontal slices, backfilling after each level before moving up.

-

Longwall Mining. This technique uses a shearer to cut coal from the face of a long tunnel.

-

Shrinkage Stope Mining. A highly productive method used for steep orebodies, involving multiple stages of blasting.

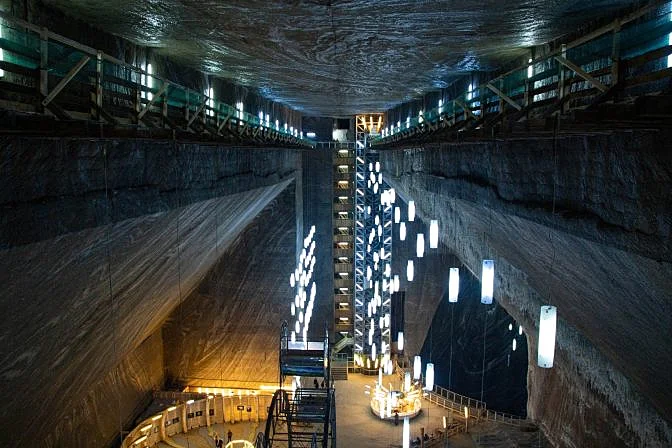

Salt mine | Source: Szabolcs Molnar from Pixabay

Salt mine | Source: Szabolcs Molnar from Pixabay

Mining Equipment for Soft Rock vs. Hard Rock Mines

The type of equipment used varies depending on whether the rock is soft or hard. Soft rocks like salt or coal do not require explosives, while hard rocks like gold or copper often do.

Soft rock mining relies on specialized machinery, while hard rock mining frequently involves drilling and blasting techniques to access valuable minerals.

Mining Tools and Equipment

Mining involves a wide range of tools, from traditional hand tools to advanced machinery. To help organize this information, we’ve grouped the tools by the type of mining method they’re used in.

Before diving into specifics, here’s a general overview of the categories of mining tools:

- Miner Tools – Handheld tools like pickaxes and shovels.

- Mining PPE – Personal protective equipment for safety.

- Surface Mining Equipment – Tools used in open-pit and strip mining.

- Underground Mining Equipment – Machinery designed for confined spaces.

Now, let's take a closer look at each category.

Mining PPE

Personal protective equipment (PPE) is essential for miners to stay safe in hazardous environments. Common PPE includes:

- Air Respirators

- Cap Lights

- Hearing Protection

- Miner’s Pouch

- Protective Communications

- Protective Eyewear and Headwear

- Reflective Clothing

- Self-Rescuers

Surface Mining Equipment

Surface mining uses a variety of heavy machinery, including:

- Blasthole Drills – For placing explosives.

- Bucket-Wheel Excavators – Used in open-pit mining for continuous excavation.

- Dozers – Move large amounts of dirt and debris.

- Dragline Excavators – Remove overburden in strip mining.

- Drones – For surveying and inspecting mine sites.

Blasthole drill | Source: Cat Models

Blasthole drill | Source: Cat Models

Underground Mining Equipment

Underground mining requires specialized equipment such as:

- Continuous Miners – For cutting coal from seams.

- Drones – For inspecting hard-to-reach areas.

- Jumbo Drills – For creating holes for explosives.

- Loaders and Haulers – For transporting minerals underground.

- Refuge Chambers – For emergency shelter during accidents.

Elios 3 drone | Source: Flyability

Elios 3 drone | Source: Flyability

Other Mining Tools

In addition to the above, there are other tools used in both surface and underground mining, such as conveyors, crushers, and screens. These tools are vital for processing and transporting minerals efficiently.

Mining Tools: rugged and ready for hard work

The mining industry has been around for thousands of years, and even today, it demands tough, reliable equipment. With the rise of digitalization, technologies like LiDAR and drones are becoming increasingly important for mapping and inspecting mines safely and efficiently.

Drones like the Elios 3 are now helping to inspect underground areas that are too dangerous for humans. They provide remote access, improving safety and efficiency in mining operations. As the industry evolves, these new tools are proving to be invaluable assets in modern mining practices.

The use of small wheel loader for construction operations is very stable and reliable. Not only is the internal configuration high, but the equipment adopts a modern streamlined design, the whole machine is beautiful and generous, and the body is sprayed with plastic treatment, which has the function of rust and corrosion resistance. When working with a small Forklift, it is very easy to operate.

We have 2tons smaller loader ,1.5tons front end loader ,3tons rated loader etc .

The Wheel Loader Spare Parts all with excellent quality.

2Tons Smaller Loader,Front End Loader 1.5Tons,Samller Wheel Loaders,3Tons Rated Loader

Shandong Ocean Machinery Com.LTD , https://www.sdoceanmachine.com