Inspecting 63 Tanks with 2 Drones in 2 Weeks

The Elios drone helped TDBR Inspections revolutionize tank inspections at the 3R-2 rig off the coast of Brazil

Benefits In A Nutshell

|

Speed With just two staff members, the Elios 2 and Elios 3 completed inspections of 63 tanks in just 14 days. This is a massive improvement over traditional methods, which would have taken months and required three or more people. |

Safety Using drones eliminated the need for personnel to enter confined spaces or work at height. This removed the requirement for special permits, making the process safer and more efficient overall. |

|

Accuracy |

Efficiency By using drones, the number of people on board (PoB) was kept within limits, allowing engineers and workers to be present instead of dedicated inspection teams. This improved site efficiency and reduced downtime. |

Working offshore presents unique challenges. Equipment failure or delayed materials can lead to long delays, downtime, or even safety risks. Space is limited, so there's a constant need to balance inspections, maintenance, and operational efficiency. That’s why finding smarter, faster, and safer solutions is critical.

Customer Needs: Challenging Inspections For An Offshore Rig

The 3R-2, a TLWP-type oil rig located off the coast of Brazil, faces significant inspection challenges. With a maximum PoB of around 60 people, every individual must be carefully planned and scheduled. Staff are transported by helicopter, so optimizing their presence on the platform is essential to maintain productivity without overloading the site.

The tanks being inspected are very high, making them difficult to inspect manually

Inspection of large onboard tanks is particularly challenging. Traditional methods require multiple staff using ropes, which can take days per tank. The facility is 10 years old and must meet strict regulatory standards. Any inspection results are used to update records, so accuracy is key. The challenge is how to gather this data efficiently without bringing in large inspection teams for extended periods.

Solution: Using Drone Inspections To Save Time

TDBR Inspections, a drone service provider based in Brazil, has extensive experience with complex inspections using the Elios drone. They were contacted by Raul Martini, a naval engineer from 3R Petroleum, who owns the 3R-2. Their goal was to use the Elios drone for tank inspections and see if it could reduce time and improve efficiency.

The Elios 2 (upper) and Elios 3 (lower) outside the narrow entry for a tank

The Elios 2 (upper) and Elios 3 (lower) outside the narrow entry for a tank

The main objective was to collect visual data about the condition of the tanks. TerraDrone aimed to create an archive of images that could be used for visual inspections, defect identification, and fault detection. Areas of concern could then be marked for further action. The project involved over 70 tanks, and TDBR planned to visit the site four times to gather all necessary data.

Using the Elios drone offered several advantages: time and cost savings, simplified logistics, and no need for special permits. The data collected was also submitted to the Class Society for verification. If successful, this could lead to a long-term partnership between TDBR and 3R Petroleum for routine inspections on the 3R-2.

Results: Inspecting 63 Tanks In 88 Flights

A team from TDBR Inspections traveled to the 3R-2 to begin planning the flight operations as part of Phase 1. They conducted reconnaissance flights using the Elios 2 to scout the tanks and plan the inspection routes.

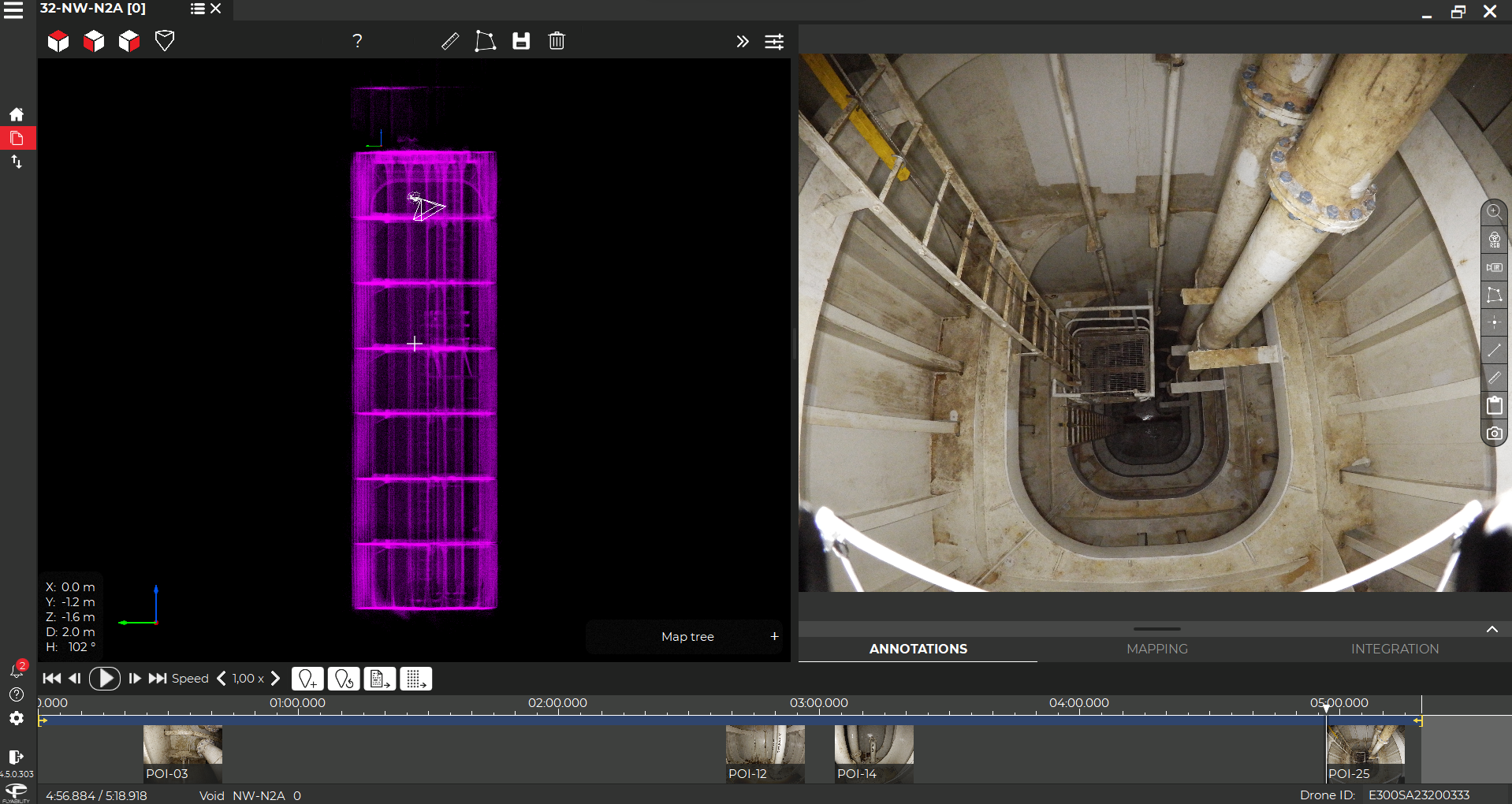

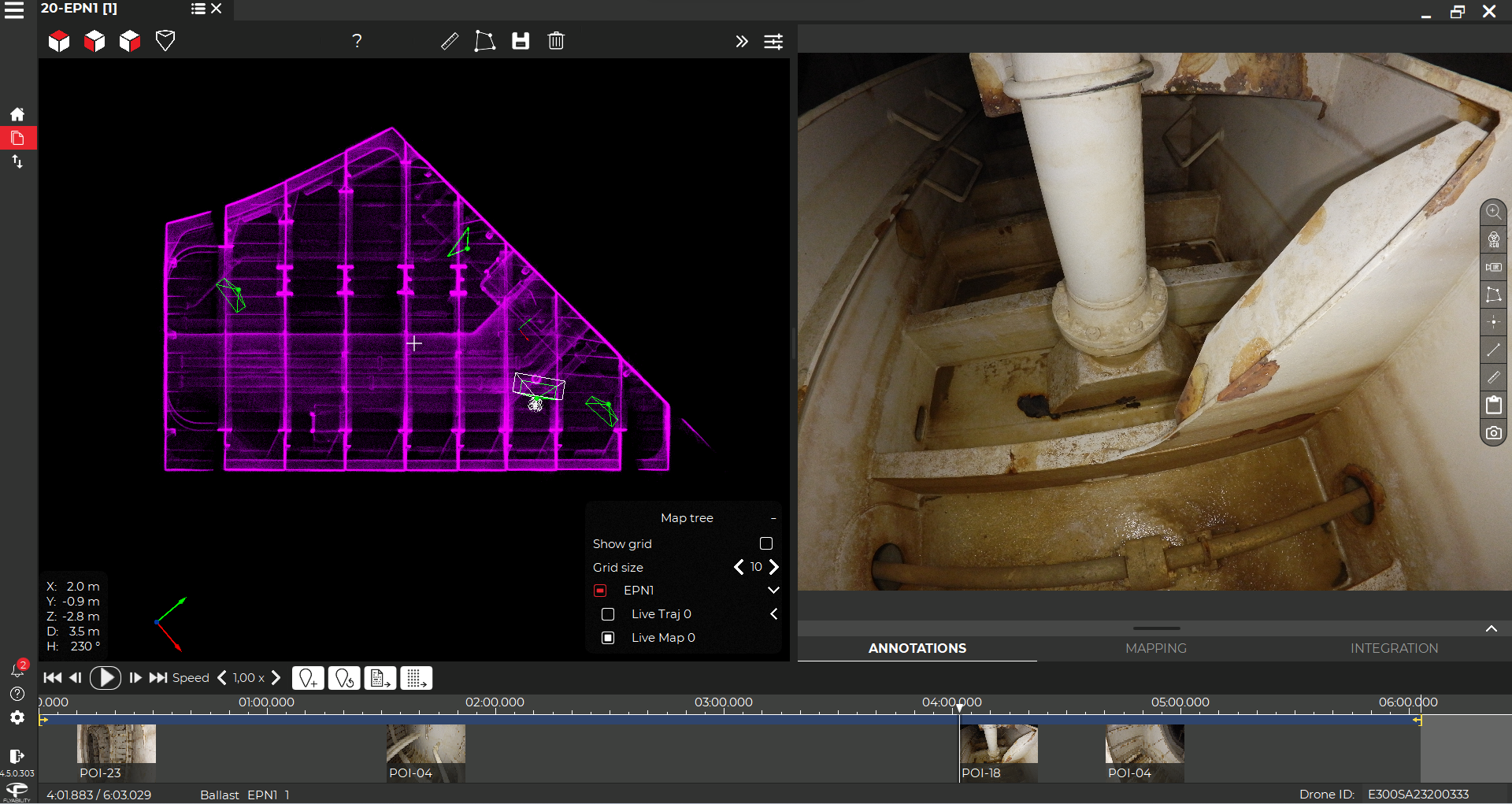

The inside of a ballast tank visualized with the Elios 3

After completing initial external flights, the team returned a month later for Phase 2. During this time, they purchased an Elios 3 and brought both drones to the site. Over the course of 14 days, pilots flew 88 separate flights across 63 tanks, spending over 10 hours in the air.

The data was processed in Inspector 4, where visual inspections were used to update records and identify anomalies. The Elios 3’s LiDAR data created detailed 3D models of the tanks’ interiors, providing valuable insights without requiring any human entry into confined spaces.

Conclusion: A Longterm Strategy For Faster Rig Inspections

The scale of this project was impressive—inspecting 63 tanks in just two weeks equates to over 10 assets per day. This is a dramatic improvement compared to traditional methods, which might take up to a week for a single tank with multiple rope access technicians. With the Elios 3, two people could complete the same task in just two days.

TDBR Inspections plans to conduct similar inspections at the 3R-2 and other sites in the future. The increased efficiency not only saved time and costs but also optimized the movement of staff, helping manage the PoB effectively. The Elios drone proved to be a safe, accurate, and reliable solution that met regulatory requirements and addressed a real industry challenge.

Discover more about the Elios 3 and its applications to see how it can transform your inspection processes today.

Citric acid is the largest organic acid produced by biochemical methods in the world. Citric acid and salts are one of the pillar products of the fermentation industry. They are mainly used in the food industry, such as acid, solvent, buffer, antioxidant, deodorant, flavor enhancer, gelling agent, and toner. [9]

In terms of food additives, it is mainly used for carbonated drinks, fruit juice drinks, lactic acid drinks and other cool drinks and pickled products, and its demand is subject to seasonal climate changes. Citric acid accounts for about 2/3 of the total consumption of acid flavor agent. Adding citric acid to canned fruit can maintain or improve the flavor of fruit, increase the acidity of some fruits with low acidity (lower pH value), weaken the heat resistance of microorganisms and inhibit their growth, and prevent the bacterial can-breaking and damage that often occur in canned fruit with low acidity. Adding citric acid into candy as an acid is easy to coordinate with fruit taste. The use of citric acid in gel food, jam and jelly can effectively reduce the negative charge of pectin, so that the hydrogen bond between pectin molecules can bind to gel. When processing canned vegetables, some vegetables show alkaline reaction. Using citric acid as pH regulator can not only play a role in seasoning, but also maintain its quality. Citric acid has the characteristics of chelation and pH regulation, which can increase the performance of antioxidants, inhibit enzyme activity, and extend the shelf life of foods in the processing of quick-frozen foods.

Metal cleaning

Citric acid is an organic acid produced by microbial fermentation. It is widely used in Detergent production. Its specificity and chelation play a positive role. Citric acid has good performance in the actual use process, mainly in terms of safety. The raw materials for preparation of citric acid are from grain, which is a safe food-grade microorganism. The use of citric acid will not affect the environment. It is easy to degrade under the action of microorganisms and heat. Its own chelating ability is also relatively strong. The main reason is that citrate has relatively strong chelating ability for manganese ion and iron ion, and the use effect is also prominent. The corrosion inhibition of citric acid in detergents is also prominent. As an important part of chemical cleaning, acid pickling is relatively weak compared with inorganic acid. Therefore, the corrosivity of citric acid to equipment is relatively small. The safety and reliability of citric acid cleaning is relatively strong, and the waste liquid is relatively easy to be treated, which will not cause harm to human body.

Fine chemical industry

Citric acid is a kind of fruit acid, which is mainly used to accelerate the renewal of cutin, and is commonly used in lotion, cream, shampoos, whitening products, anti-aging products, acne products, etc. Citric acid can be used as chemical analysis reagent in chemical technology, as experimental reagent, chromatographic analysis reagent and biochemical reagent; Used as complexing agent and masking agent; To prepare buffer solution. The use of citric acid or citrate as a detergent aid can improve the performance of washing products, rapidly precipitate metal ions, prevent pollutants from re-attaching to the fabric, and maintain the necessary alkalinity for washing; Disperse and suspend dirt and ash; It is an excellent chelating agent to improve the performance of surfactant; It can be used as a reagent to test the acid resistance of architectural ceramic tiles. Citric acid-sodium citrate buffer is used for flue gas desulfurization. China is rich in coal resources, which constitute the main part of energy. However, there has been a lack of effective flue gas desulfurization technology, resulting in serious atmospheric SO2 pollution. Because of its low vapor pressure, non-toxic, stable chemical properties and high SO2 absorption rate, citric acid-sodium citrate buffer solution is a desulfurization absorbent with great development value.

Sterilization and coagulation process

The combined action of citric acid and 80 ℃ temperature has a good effect on killing bacterial spores, and can effectively kill the contaminated bacterial spores in the pipeline of hemodialysis machine. Calcium ion must be involved in the formation of prothrombin activator and subsequent coagulation process. Citrate ion and calcium ion can form a soluble complex that is difficult to dissociate, thus reducing the concentration of calcium ion in blood and preventing blood coagulation.

Animal breeding

Citric acid is formed by the carboxylation of acetyl coenzyme A and oxaloacetic acid in the body's tricarboxylic acid cycle, and participates in the metabolism of sugar, fat and protein in the body. Natural citric acid exists in the fruits of plants (such as lemon, orange, pineapple, etc.) and in the bones, muscles and blood of animals. Artificial synthesis is made by fermentation of sugar-containing substances such as sugar, molasses, starch, grapes, etc. Adding citric acid to the formula feed can disinfect, prevent mildew and prevent Salmonella from infecting animal feed. Animal intake of citric acid can reduce the proliferation of pathogens, inhibit the production of toxic metabolites, and improve animal stress.

Agriculture

In November 2022, Chinese scientists found that the selection of organic acids (flavors) such as citric acid was completed in the process of watermelon improvement

citric acid powder,lemon acid, citric acid for food,manufactured citric acid

Henan Chuange Industry CO.,LTD , https://www.chuangegroup.com