Eliminating Downtime for a Train Station Roof Inspection with Elios Drones

With the need to avoid disruptions to rail operations, an inspection team in the Netherlands turned to the Elios 3 drone to inspect the roof of a train station. This innovative approach allowed them to complete the task efficiently and safely without affecting regular train services.

Key Benefits at a Glance

|

Access The complex structure of the train station made it difficult to reach the roof for inspection. Traditional methods required scheduling train downtime up to 13 weeks in advance. Instead, the Elios 3 was used to gather data during nighttime hours when fewer trains were running, avoiding any service interruptions. |

No Downtime By conducting inspections at night using the Elios 3, the NS Stations team avoided disrupting rail traffic, ensuring that public transport remained unaffected. Previously, such work would have required closing three train lines and de-energizing the catenary system. |

|

Safety The challenging structure made it unsafe for personnel to access the roof. The Elios 3 provided a safe alternative, eliminating risks to staff and minimizing disruption to passengers. |

Speed Data collection was completed during nighttime hours, when there were fewer trains and people around. The process was done in just two flight sessions, significantly reducing time and effort compared to traditional methods. |

Delays in railway services can cause frustration for passengers and disrupt supply chains. Maintaining infrastructure like tracks, signal boxes, and stations is crucial for smooth operations. However, inspecting structures like train station roofs while trains are running poses a major challenge. That’s where drones come in.

At one station in the Netherlands, the team faced difficulties inspecting the roof due to its age and complex design. The metal beams needed careful analysis, but accessing them safely was nearly impossible without causing disruptions. They needed a solution that would allow them to collect accurate data without shutting down operations or risking safety.

The Elios 3 has already inspected a railway bridge — but what about a train station?

Customer Needs: Accessing the Roof Structure of a Train Station

Vortex Hardware & Maintenance BV, a drone and robotics specialist in the Netherlands and a Flyability partner, has collaborated with NS Stations on various maintenance projects across the country. Their experience with the Elios 3 made it a natural choice for this particular challenge.

One station had concerns about the structural integrity of its roof, built in the early 1900s. Inspecting the space between the metal beams and the roof was essential, but traditional methods would require scaffolding, which would disrupt train services. Without accurate data, maintenance decisions had to be based on worst-case assumptions.

The Elios 3 offered a safe and efficient way to collect the necessary data without disrupting operations, making it the ideal solution for this project.

Solution: Inspecting a Train Station with the Elios 3

Experienced operators from NS Stations, Vortex, and Flyability had previously used the Elios 2 to inspect a pedestrian bridge. Now, they were confident the Elios 3 could handle the more complex environment of a train station.

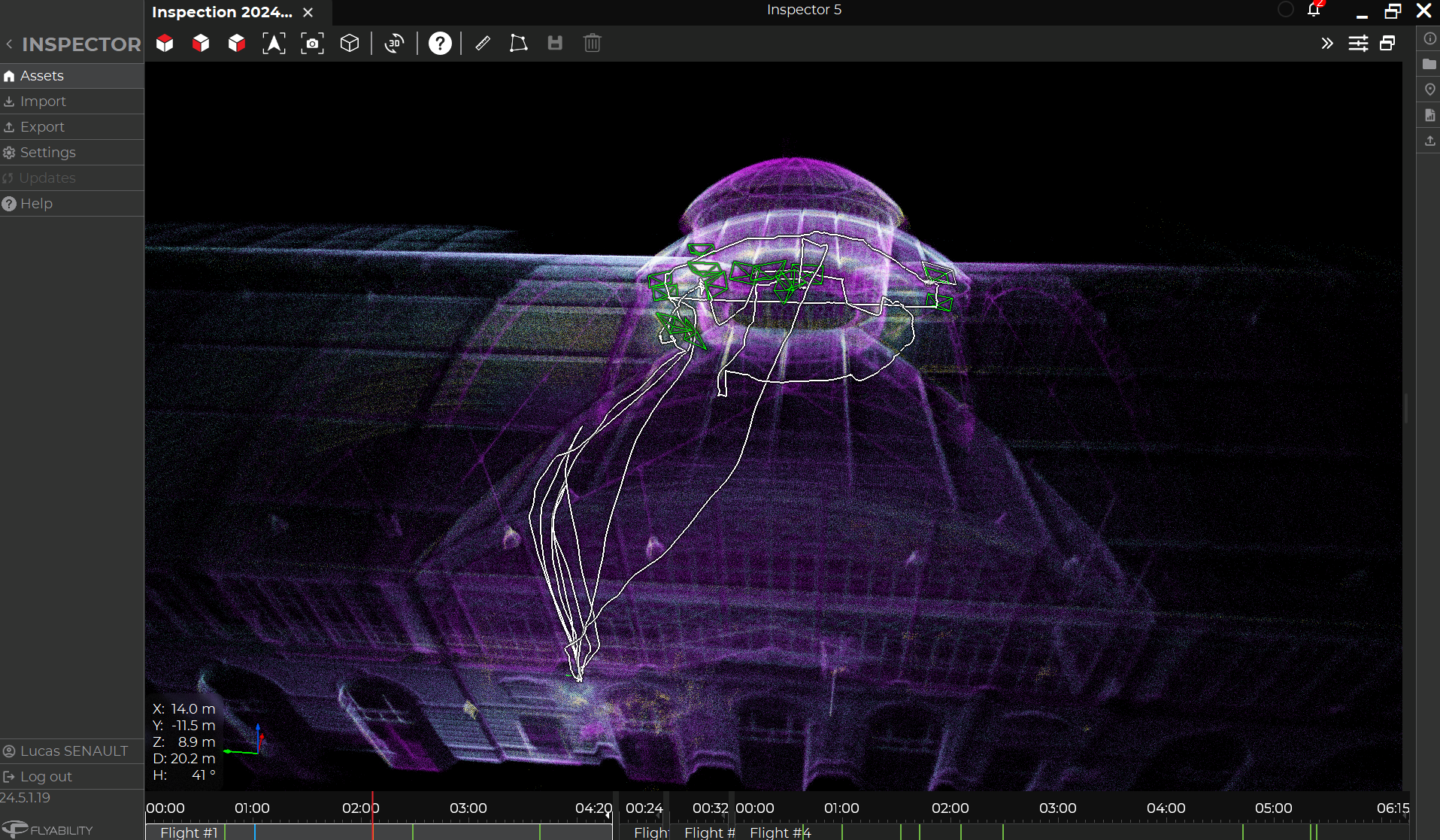

The LiDAR scan of the train station with the Elios 3 captured complex structures, including this protruding element in the roof

They planned to use the Elios 3’s LiDAR payload to detect defects and anomalies in the station's structure. A ground-based LiDAR scanner was also used to plan the flight path, ensuring compliance with safety regulations and avoiding areas with high foot traffic or train activity.

Inspections were conducted at night to minimize disruptions. The team also coordinated with Air Traffic Control due to the proximity of a nearby airport. This ensured safe and legal operation of the drone in a sensitive environment.

Results: Flying the Elios 3 at Night

After initial reconnaissance with the Elios 2, the team used the Elios 3 to conduct a detailed inspection. A pre-planned route was followed, focusing on key areas of concern and performing a general review of the entire structure.

The Elios 3 flew at night around the station to gather data — can you spot it in the photo?

A construction adviser was present to guide the inspection and highlight areas of interest. To ensure safety, two observers monitored the platform and communicated with the pilot to avoid flying over active trains.

The Benefits of the Elios 3 Drone for Infrastructure Inspections

Previously, similar inspections required significant planning, including scaffolding, train line closures, and power shutdowns. This process was slow, inefficient, and limited in terms of data availability. With the Elios 3, inspections became faster, safer, and more precise.

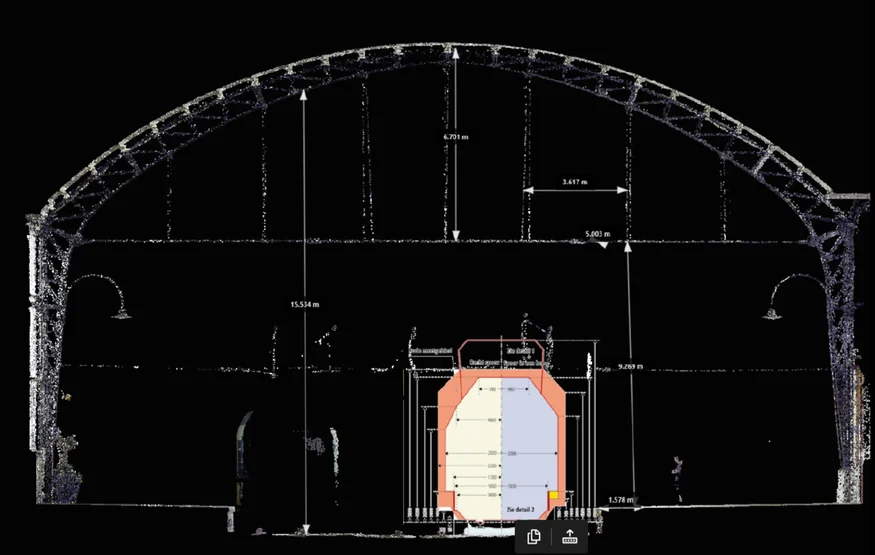

The entire building structure could be visualized with the LiDAR point cloud, along with distance measurements

The Elios 3’s built-in lighting system, providing 16,000 lumens, ensured clear visibility even in low-light conditions. Its compact design and maneuverability made it ideal for navigating tight spaces and complex structures.

The Elios 3 in Future Railway Infrastructure Inspections

Vortex and NS Stations had already gained recognition for their drone-based inspections in the Netherlands. This project took their capabilities to the next level by providing unprecedented insight into the station’s structure without compromising safety or efficiency.

Instead of full-scale renovations, maintenance was targeted only where needed, saving time, money, and operational disruption. The use of drones enabled proactive maintenance planning, reducing the need for lengthy and costly interventions.

The Elios 3 saved weeks of work, unnecessary work at height, and did not disrupt rail traffic

ProRail, the client for this project, praised the use of the Elios 3, stating it offers greater flexibility and reduces the need for scaffolding. It also allows for more targeted inspections, improving overall efficiency and reducing inconvenience for travelers.

With the ability to visualize assets in 3D, railway managers can now make informed decisions based on real-time data rather than estimates. The Elios 3 has proven to be a game-changer in modern infrastructure inspection, setting a new standard for safety, speed, and accuracy.

Discover more about the Elios 3 and its applications in infrastructure inspection today.

Sodium Hexametaphosphate,Sodium Hexametaphosphate Shmp,Shmp Sodium Hexametaphosphate,CALGON

Henan Chuange Industry CO.,LTD , https://www.chuangegroup.com