Eliminating Downtime for a Train Station Roof Inspection with Elios Drones

In the Netherlands, an inspection team faced the challenge of inspecting a train station’s roof without disrupting rail operations. To avoid any delays, they turned to the Elios 3 drone, offering a safe and efficient alternative to traditional methods.

Key Benefits in a Nutshell

|

Access The unique structure of the train station made it impossible for inspectors to reach the roof safely. Traditional inspections required scheduling train downtimes up to 13 weeks in advance. Instead, the Elios 3 was deployed at night, navigating the area of interest without affecting daily operations. |

No Downtime By conducting inspections at night using the Elios 3, the NS Stations team avoided disrupting rail traffic. This meant no changes to public transport schedules. In the past, such work would have required closing three train lines and de-energizing the catenary system. |

|

Safety The complex structure of the station made manual access dangerous. The Elios 3 allowed data collection without putting staff or passengers at risk, making it a safer option for everyone involved. |

Speed Data collection was completed during nighttime hours when fewer trains and people were around, reducing risks and allowing the task to be finished in just two flight sessions. |

Unplanned delays on railways can cause major inconvenience, not only for passengers but also for freight operations that rely on precise schedules. Ensuring the smooth operation of rail infrastructure is essential, especially when it comes to critical structures like train station roofs.

Inspecting these areas while trains are running has always been a challenge. Manual inspections require significant planning and often result in service disruptions. So, what's the solution? Enter the Elios 3 – a powerful tool that allows for safe, efficient, and timely inspections without interrupting daily operations.

The Elios 3 has already inspected a railway bridge – but what about a train station?

Customer Needs: Accessing the Roof Structure of a Train Station

Vortex Hardware & Maintenance BV, a Dutch partner of Flyability, has collaborated with NS Stations on various railway maintenance projects. They’ve successfully used drones for infrastructure inspections, including bridges and other hard-to-reach structures. One particular station had a concern about its aging roof structure, built in the early 1900s.

The space between the metal beams and the roof needed careful analysis, but manual access was unsafe and disruptive. Without accurate data, maintenance decisions were based on worst-case assumptions. The Elios 3 provided a safe and effective way to gather the necessary information without stopping train services.

Solution: Inspecting a Train Station with the Elios 3

With prior experience using the Elios 2 for similar tasks, the team was confident in the capabilities of the Elios 3. The LiDAR payload enabled precise mapping of the structure, identifying defects and anomalies with high accuracy. They planned the flights carefully, ensuring compliance with safety regulations and avoiding interference with train operations.

Flights were conducted at night to minimize disruption and ensure safety. The team also coordinated with Air Traffic Control due to the proximity of a nearby airport. Using ground-based LiDAR scans helped plan the drone’s route and avoid restricted zones.

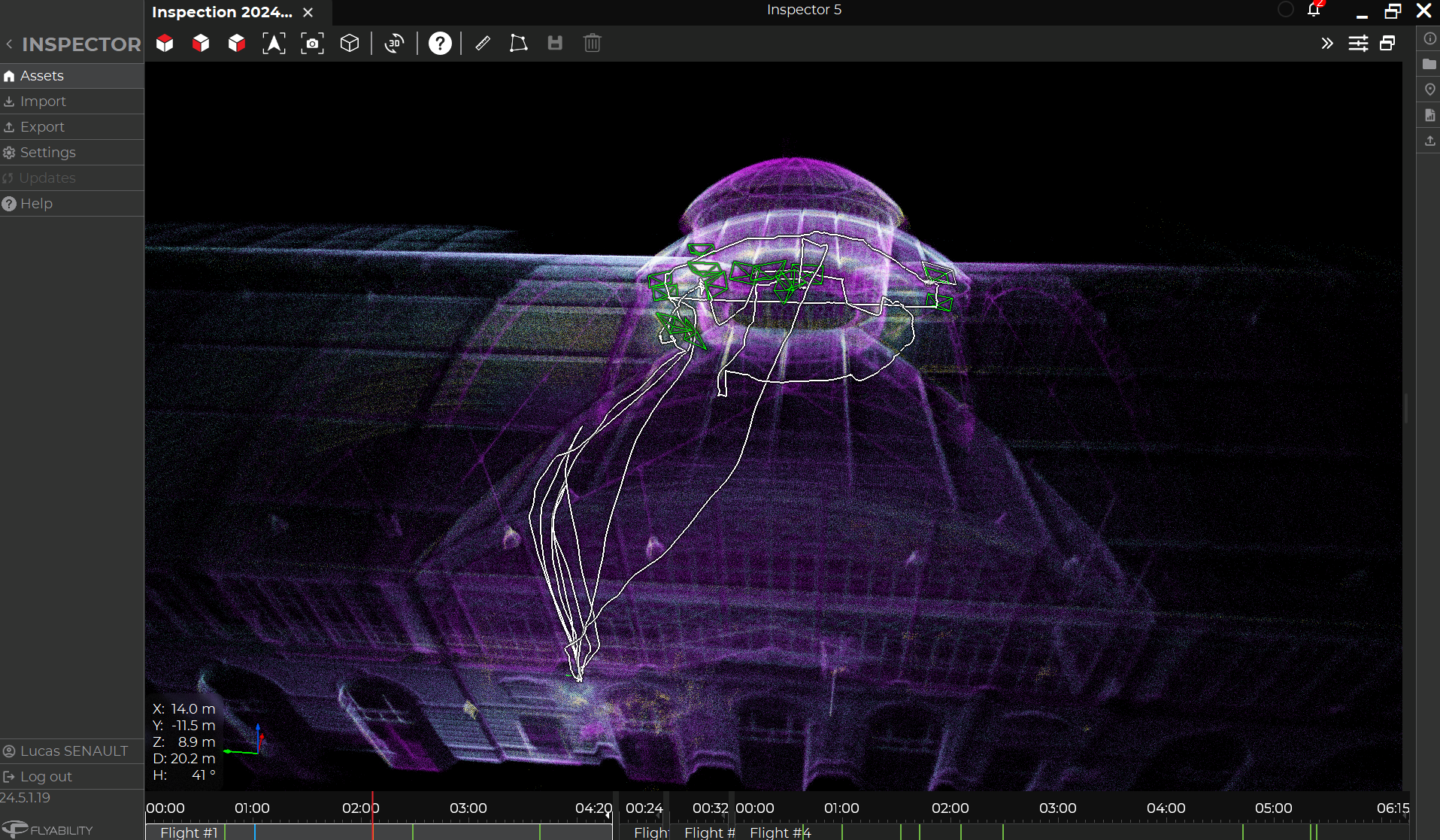

The LiDAR scan of the train station with the Elios 3 captured complex structures, including this protruding element in the roof

Results: Flying the Elios 3 at Night

Ruben, along with Remco and Sep from NS Stations, conducted reconnaissance flights using the Elios 2 before deploying the Elios 3. The pre-planned route focused on areas of concern, with a construction adviser on-site to guide data collection.

The main challenge was avoiding flights during train movements. Two observers on the platform monitored train activity and communicated with Ruben to prevent any conflicts. The use of the Elios 3’s 16,000-lumen lighting system ensured visibility even in low-light conditions.

The Elios 3 flew at night around the station to gather data – can you spot it in the photo?

The Benefits of the Elios 3 Drone for Infrastructure Inspections

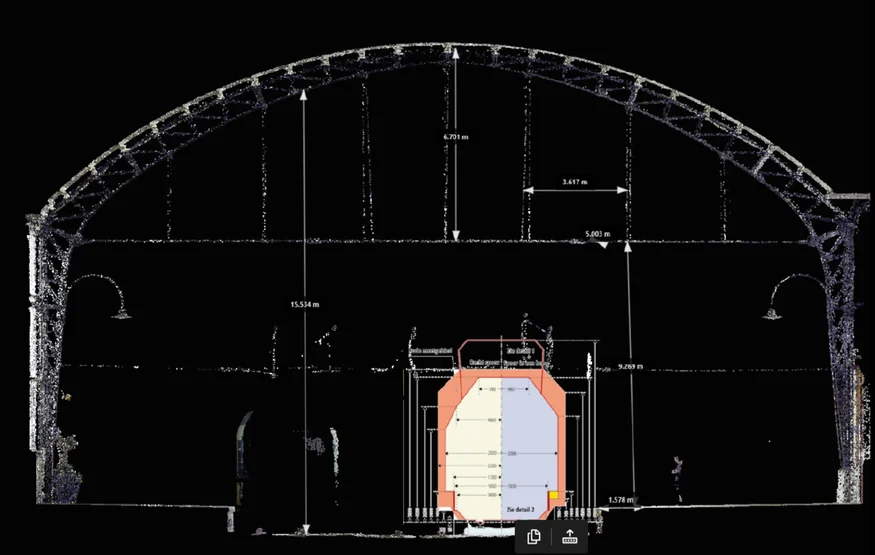

Previously, such inspections required scaffolding, train line closures, and long lead times. Now, with the Elios 3, data can be collected quickly and safely, reducing downtime and improving decision-making. The LiDAR point cloud provided detailed 3D visualizations of the entire structure, enabling precise planning and targeted maintenance.

The entire building structure could be visualized with the LiDAR point cloud, along with distance measurements

The Elios 3 significantly reduced risks associated with manual inspections, such as electrocution hazards and collisions with trains. Its compact design and advanced features made it ideal for navigating tight and complex spaces.

The Elios 3 in Future Railway Infrastructure Inspections

Vortex and NS Stations have already gained recognition for their innovative use of drones in railway inspections. This project marked a new milestone, providing unprecedented insight into station infrastructure without compromising safety or service.

Maintenance was performed only where necessary, avoiding full-scale station shutdowns. This approach saved time, money, and resources, with cost savings reaching millions of euros. ProRail praised the use of the Elios 3, highlighting its flexibility and efficiency compared to traditional methods.

The Elios 3 saved weeks of work, unnecessary work at height, and did not disrupt rail traffic

With real-time 3D data available at the touch of a button, railway managers can now make informed decisions without relying on outdated assumptions. The Elios 3 is setting a new standard for infrastructure inspections, proving that technology can deliver both safety and efficiency in complex environments.

Discover more about the Elios 3 and its applications today.

Titanium Dioxide DOGUIDE Brand

Doguide`s main products are sr2377 Titanium Dioxide, sr237 titanium dioxide, SR240 titanium dioxide and other products.

Doguide titanium dioxide sr-2377 uses zirconia and alumina for inorganic and organic surface treatment. It is designed to have good whiteness and excellent gloss,

High coloration, durability, and good dispersion.

Product features

·Good whiteness

·Excellent gloss

·High coloration

·Good durability

·Good dispersion

Sr-2377 is recommended for indoor or outdoor coatings, emulsion / powder coatings, printing inks, primers, rubber, masterbatch, plastics and other applications.

Titanium dioxide Shandong Dongjia sr-240

Sr-240 titanium dioxide is a rutile titanium dioxide pigment with inorganic surface treatment and organic surface treatment,

It has good gloss and covering power, anti pulverization, easy to disperse in plastic and rubber.

application area

Masterbatch, plastic, rubber, flexible PVC

1: High dispersion

2: High gloss Resistance to pulverization

3: Strong covering power

4: Bluish phase

5: It is easy to disperse in plastic and rubber and has good stability

6: Good weather resistance

Recommended applications: Color Masterbatch, plastic, flexible PVC, rubber, etc

Titanium Dioxide Doguide Brand,Coating Titanium Dioxide,Titanium Dioxide For Coating,Tio2 Titanium Dioxide Sr-2377

Henan Chuange Industry CO.,LTD , https://www.chuangegroup.com