Â

Â

LED technology has completely transformed the lighting industry. Compared to traditional light sources like incandescent and fluorescent bulbs, LEDs are far more energy-efficient, provide better light quality, and last significantly longer—making them a top choice across various industries. According to the U.S. Department of Energy, LED lighting accounted for 48% of installed lighting units in 2020, up from just 8% in 2015 and a mere 1% in 2010.

Â

As LED adoption continues to grow, so does the competition among manufacturers to produce brighter and more efficient fixtures. A key metric used to describe this performance is “luminous efficacy,†which measures how effectively a light source converts electrical power into visible light. While this metric is useful, it's also becoming a point of confusion due to some misleading practices by manufacturers.

Â

One common tactic is to test only the bare LED chip instead of the complete fixture, including lenses and other optical components. This gives artificially high efficacy numbers that don’t reflect real-world performance. The result? Confusion for specifiers and end-users who can't accurately compare products or understand the true output of a system.

Â

In this article, we’ll explore what luminous efficacy really means, why it’s important in solar lighting, how some manufacturers mislead with their claims, and tips to help you identify genuine, high-performance LED fixtures.

Â

What is Luminous Efficacy?

Â

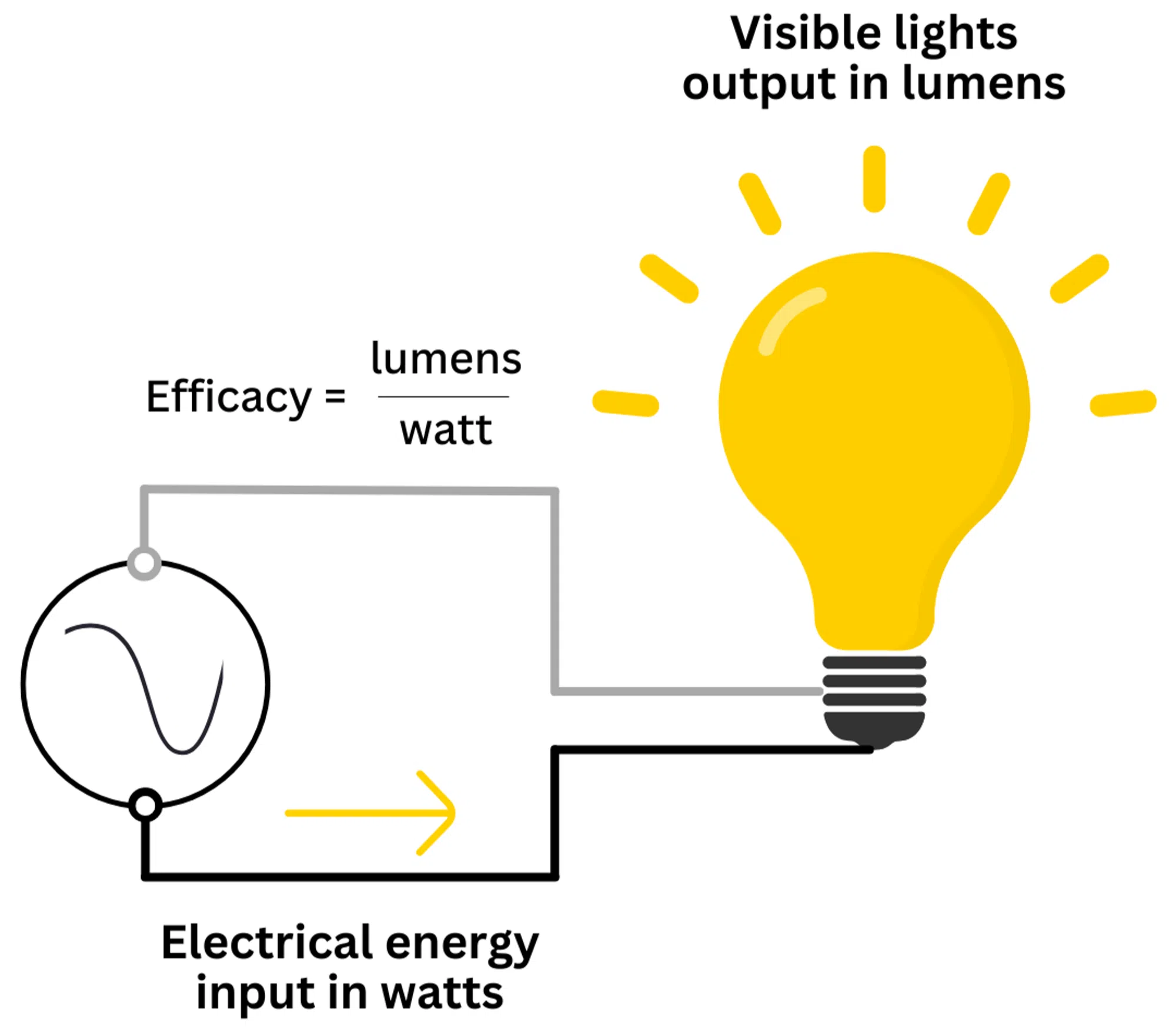

The Illuminating Engineering Society (IES) defines luminous efficacy as "the total emitted luminous flux divided by the total source electrical input power." It's typically measured in lumens per watt (Lm/W). For example, if a fixture emits 1500 lumens using 20 watts, its efficacy is 75 Lm/W. If another emits 2500 lumens at the same 20 watts, its efficacy is 125 Lm/W—significantly higher because it produces more light with the same power.

Â

Â

While efficacy is often confused with efficiency, they are different concepts. Efficacy measures how much light is produced per watt of power, while efficiency refers to how much of that light is actually delivered to the desired area. Efficacy is the better metric for comparing fixtures, but it's crucial to understand the difference between the two terms.

Â

Why Does It Matter for Solar Lighting?

Â

For grid-connected systems, higher efficacy means lower energy costs and less strain on the power grid. But when it comes to solar lighting, where energy is free and abundant, does efficacy still matter? Absolutely.

Â

A higher-efficacy fixture uses fewer watts to produce the same amount of light, which reduces the size and number of solar panels and batteries needed. This makes solar lighting more affordable and practical, especially in high-latitude areas where sunlight is limited. It also allows manufacturers to design smaller, more cost-effective systems.

Â

How Do Manufacturers Misrepresent Efficacy?

Â

To attract buyers, some manufacturers test only the LED chip without the lens or driver, inflating their efficacy numbers. These results look impressive on paper, but they don't reflect real-world performance. Lenses play a critical role in distributing light evenly, so excluding them isn't an option in actual installations.

Â

Many manufacturers fail to clarify whether their reported efficacy includes the full fixture or just the LED chip. This lack of transparency makes it hard for buyers to compare products fairly. However, there are ways to verify the accuracy of these claims.

Â

The Importance of LM-79 Testing

Â

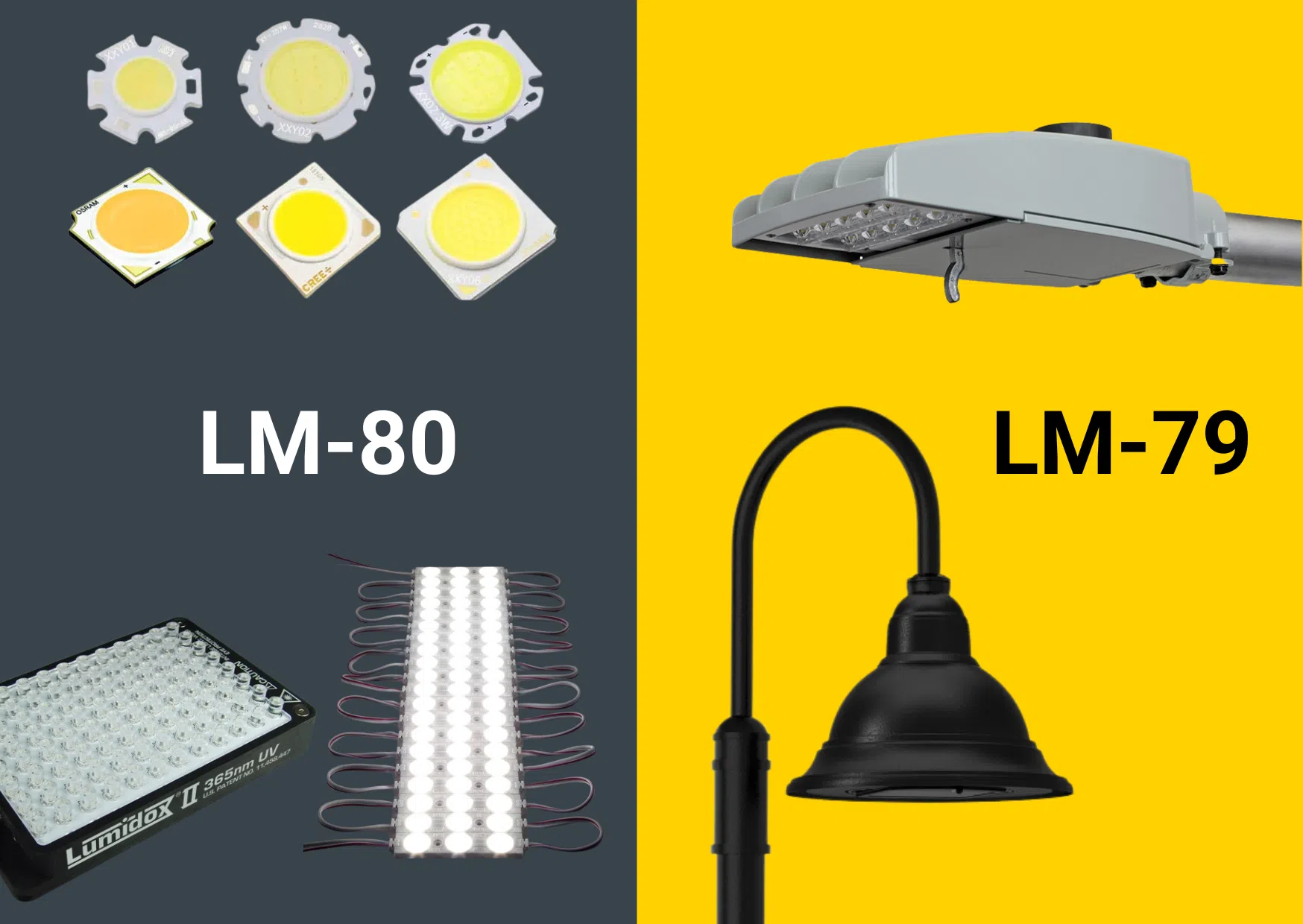

LM-79 is a standardized testing method approved by the IES for measuring the optical and electrical characteristics of solid-state lighting products. It tests the entire fixture, including lenses and drivers, ensuring accurate and comparable data across brands.

Â

This test is essential because it provides reliable information about lumen output and efficacy. Other tests like LM-80 focus on long-term performance, not initial output. Always check for LM-79 reports when evaluating LED fixtures.

Â

Â

Other Red Flags to Watch For

Â

Look out for unrealistic efficacy ratings that fall outside the range of reputable manufacturers. Most high-quality LED fixtures have efficacies between 120 and 160 Lm/W. If a product claims significantly higher or lower, ask for clarification and independent verification.

Â

Another red flag is a constant efficacy rating across different wattage levels. Higher wattage should result in lower efficacy, and vice versa. If a manufacturer claims the same efficacy at all outputs, it's likely misleading.

Â

Making Informed Purchase Decisions

Â

Understanding luminous efficacy is essential for making smart lighting choices. Not all manufacturers measure it the same way, but standards like LM-79 help ensure consistency and reliability. When in doubt, ask the right questions:

- Can you provide independent testing results for your efficacy claims?

- How do you measure lumens in your products?

- What is the total fixture efficacy, including drivers and lenses?

- Do you have photometric reports available?

- Are your efficacy claims based on initial or maintained lumen output?

- Can you share references or case studies?

Â

If you have any questions about efficacy or anything else related to solar lighting, our team of experts is here to help. Contact us today to learn more!

Â

Epoxy Resin For Powder Coating

Powder Coating epoxy resin is a conventional solid Medium Molecular Weight (Standard Viscosity) E12 grade Epoxy Resins based on Bisphenol-A with different molecular weights and viscosities suitable for general-purpose powder coatings, electric panel boards, automobile spares, bathroom fittings, decorative articles and fixtures.

Our Advantage & Service:

-Technical Support Online Service Provided

According to customer's requirement, we provide layout (plant designer), excellent mechanical engineer, excellent electrician, etc.

-On-site Training Service Provided

In customer factory, we provide all kinds of training, including installation, commissioning

-Long-term Maintenance Provided

In the area of maintenance, we offer needs-oriented and standardized maintenance packages, such as the overhaul of components, gearboxes, in order to guarantee the safe and economic operation of plant and machinery.

-Spare Parts Replacement and Repair Service Provided

Providing spare parts for all kinds of powder coating processing equipment in long-term. And can provide tailored made spare parts according to customers' requirements. Ensure advanced craft, good material and high precision.

-Formulation Provided (our advantage)

Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings.

Powder Coating E-12,Powder Coating Epoxy Resin 604,Bpa Model Transparent Solid Epoxy Resin,Indoor Anticorrosive Decorate Epoxy Resin

Yantai Yuanli Corp Ltd , https://www.yuanlicorpcn.com